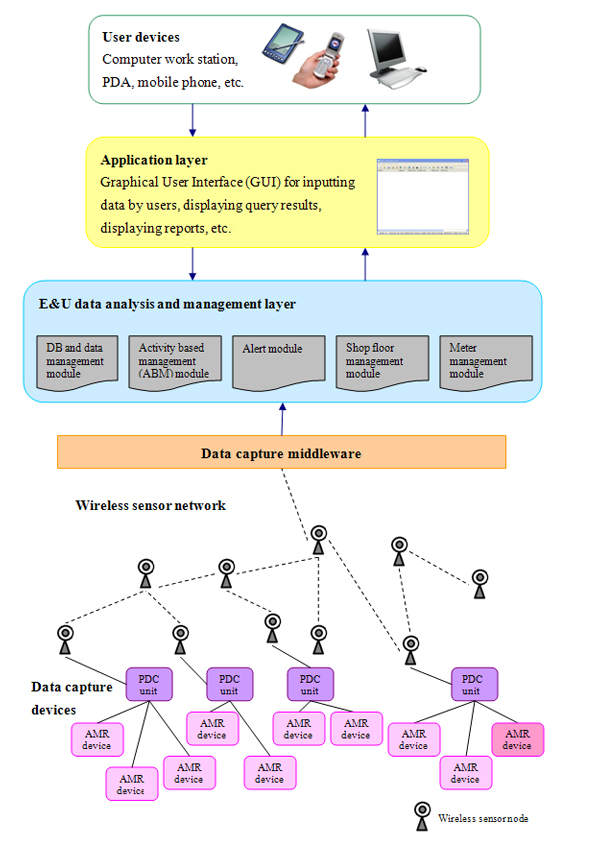

| (1) Data capture devices |

| |

|

The

data capture device, which consists of a production data capture (PDC) unit and an

automatic meter reading (AMR) device, is installed at each individual machine in the factory, to collect the required production and resource consumption data in the shop floor. |

| |

| (2) Wireless sensor network |

| |

| |

A wireless sensor network (WSN) is formed by multiple wireless sensor nodes which can act as both data receiver and sender. The real-time data captured by the data capture devices is transmitted to the data capture middleware through the WSN. |

| |

| (3) Data capture middleware |

| |

|

Data capture middleware can filter, format, organize, and combine the real-time captured production and resource data, received from the WSN. |

| |

| (4) E&U data analysis and management layer |

| |

|

This layout is the core part of the system, and it processes, manages and analyzes the data passed from the data capture middleware by different modules: |

| |

| |

- DB and data management module: Database (DB) stores the external and internal data required in the system. The data management module control the storage of data in the database, retrieval of data from the database, assess of the database, etc.

|

| |

| |

- Activity based management (ABM) module: The activity based management (ABM) module traces the overall cost directly to products by analyzing the resource consumption at each production procedure (activity). The ABC module employs different algorithms, accounting principle and logics to analyze the energy and utility consumption and cost. The ABM module provides management information for cost reduction, profitability analysis and process improvement.

|

| |

| |

- Alert module: The alerting module continuously monitors the real-time production and resource consumption data captured in the shop floor, to detect any abnormal or inefficient resource consumption. If there is any mistake or error, it will generate an alert to the users for further action.

|

| |

| |

- Shop floor management module: This module organizing the shop floor related data including the machines, workers, production orders, production schedule and production procedure, etc. With the shop floor data, the system can analyze the energy and utility consumption in different aspects of the production.

|

| |

| |

- Meter management module: The information related to meters which measuring the energy and utility consumption at each individual machine is managed by this module. The information includes which resource of which machine that the meter is measuring, which

AMR device is connected to the meter, what are the values of calibration parameters and other parameters, etc.

|

| |

| (5) Application layer |

| |

| |

It is the graphical user interface (GUI) for inputting data by users, displaying data and information, displaying query results, displaying reports, etc. |

| |

| (6) User device |

| |

| |

The users of the appropriate access rights, can access the system with their desktop computers, laptop computers, personal digital assistants (PDAs), mobile phones, etc. Users can input commands and data into the system, or obtain the required information and data from the system through the user device.

|

| |

| |

|

| |

| |